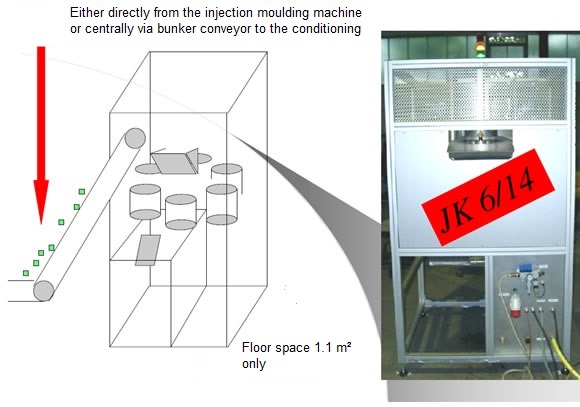

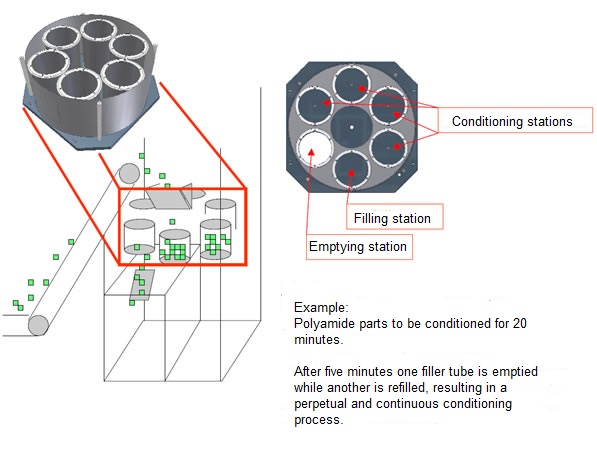

Conditioning unit JK 6/14

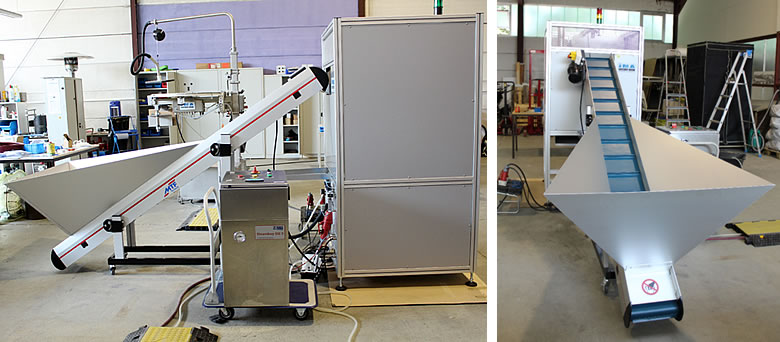

Bunker conveyor (optional)

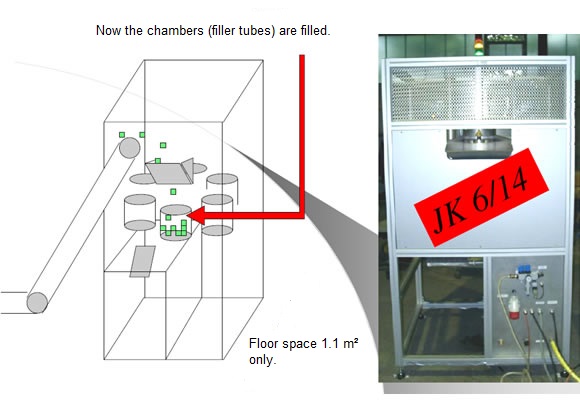

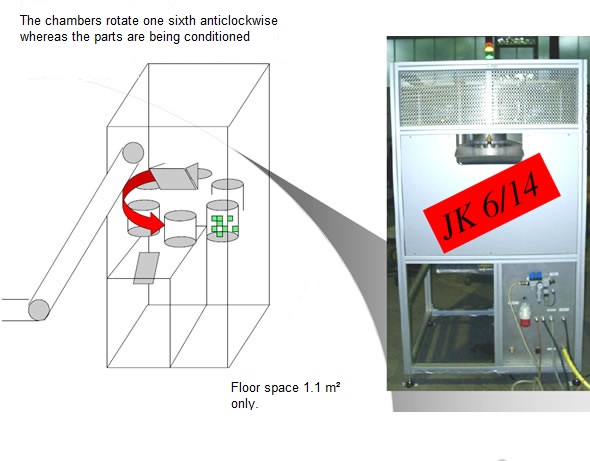

6 chambers (filler tubes) with a volume of approximately 14 litres each are available for filling.

- Conditioning either directly at the injection moulding machine or centrally

- Unbeatable short conditioning time

- Optimal tuning of the amount of humidity to be absorbed

This is the most flexible system with the least floor space requirement, suitable for large quantities of bulk material. As a proven method, this system performs conditioning procedures within an unbeatable short time. Positioned centrally, a large quantity of different articles can be conditioned automatically.

[hana-flv-player video=”https://ima-buscher.de/images/website/dokumente/6-14-ET-deutsch.flv” width=”380″ height=”auto” description=”” player=”2″ autoload=”true” autoplay=”false” loop=”false” autorewind=”true” /]

Technical Data

- Exterior dimensions L 1000 x W 1000 x H 1950 mm

- Filling height approx. 1500 mm

- Weight approx. 300 kg

Connections of conditioning unit

- device socket 400V 16A

- drain water ¾ ” external thread

- air pressure 5-6 bar

- steam connection

JK 6/14 Tandem

Two conditioning units integrated in one frame and operating synchronously are called a tandem system.

Application:

- Directly in front of assembly machines

- Avoids mixing of right and left items

- Double performance, but small floor space requirement

Steam generator with automatic desalting

Steam generator with automatic desalting

The steam generator may be installed in front of or next to the conditioning unit.

Technical Data Steam generator

Exterior dimensions L 400 x W 500 x H 800 mm

Weight 50 kg

Electrical connection 400 V 16 A.

- Control panel of the conditioning unit with control unit S7 300

- The completely conditioned PA items may be carted off via a conveyor belt.

- The condensate separator is installed under the item output of the conditioning unit. Upon output of the items it oozes a large amount of the condensate.